|

What is different about Structured Scheduling?

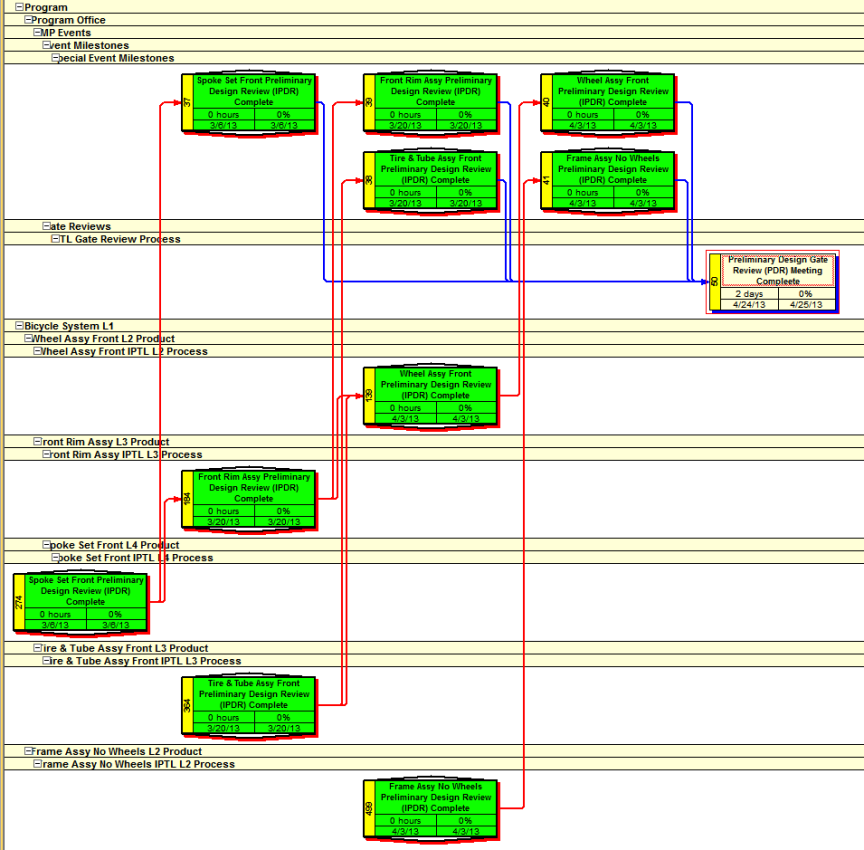

If "Structured Scheduling" uses all of the same rules; how can it be different, and help to address problems that others have had difficulty solving? There are several subtle differences that are used. With the exception of the Structnet algorithm, most of the differences are features that any scheduler should know and understand. These are just good scheduling techniques. Some of these techniques are difficult and time consuming to religiously follow when building a schedule manually. They are still good practices. Vertical linking, following the Parent/Child relationship, is one of those difficult things and is frequently ignored. particularly during the proposal process, yet it is the way drawing trees are established, assemblies are designed and systems are built. Whether it is building production units, linear or vertical production scheduling in construction, the principles are the same. The use of the Structnet algorithm is the thing that takes the drudgery out of building a schedule framework. The difference is that the Structured Schedule Framework (Framework) uses these features in a very consistent and repeatable manner for every schedule. One of the goals established when this was originally conceived was "If you put 5 schedulers in a room at 8:00 AM with the same set of criteria, by 5:00 PM, 4 of the 5 schedule frameworks would be virtually identical, would meet all of the current Government requirements, and would be ready to input durations and resources to find the critical path to each major IMP Event. The system had to be easy to teach, easy to learn, and easily understood by nontechnical members of the program team. That goal has been achieved by Structnet. The following are some of the features contained in a Structnet Structured Framework that differentiate it from many manually built schedules."

|